Quality Substrate Material

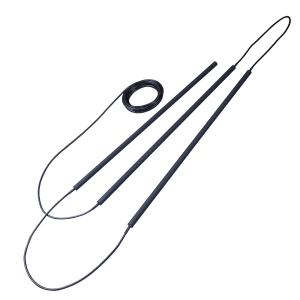

Our tubular anode is manufactured from high-tensile seamless titanium tube, which meets ASTM B338 Grade 1 standards.

Noble Metal Oxide Coating

The Ir–Ta (IrO2/Ta2O5) mixed metal oxide catalyst sintered to the surface of titanium substrate demonstrates high chemical stability when subject to high current density. We can produce anodes with differing coating thickness and noble metal oxide ratios upon request. Strict quality control procedures are followed throughout the coating process to ensure appropriate coating thickness and adhesion. Based upon accelerated life testing, conducted by an independent laboratory, our MMO coating has been proven to have an increased life expectancy when compared with other similar products on the market.

Low Electrical Resistance

The anode has an extremely low consumption rate, measured in milligrams per ampere-year. The dimensions remain nearly unchanged throughout the design life of the anode, providing a consistently low resistance.

Wide Cable Selection

PVDF, HMWPE, HALAR, XLPE, PVC or KYNAR are all optional. We recommend dual-insulated cable(such as PVDF/HMWPE) for use in ground beds with high chloride concentration. While HMWPE is an economical choice for shallow vertical and horizontal surface beds with no chlorides.