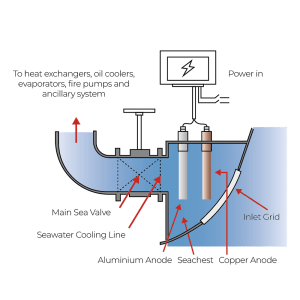

Copper anode produces copper ions which are transported by the seawater and carried into the pipework system to prevent marine growth.

Aluminum anode produces aluminum hydroxide which spread throughout the pipe work and produce an anti-corrosive layer on the internal surface of sea water cooling lines.

The size (diameter and length) of the anodes is determined based on seawater velocity (inlet water debit), design life and consideration of the maintenance or dry docking schedule for the vessels. Standard sizes range from 50mm to 150mm in diameter and 100mm to 2,000mm length.