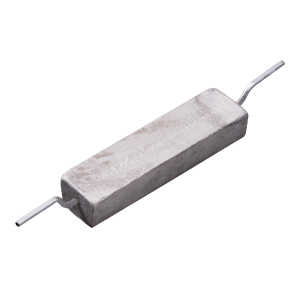

Quality Substrate Material

Casted in low-iron, high-purity alloys, our aluminum tank anode is designed to meet the standard GS EP COR 201.

| Element | GALVALUM III | DNV-RP-B401-2011 | GS EP COR 201 |

| Zinc (Zn) | 2.0% ~ 6.0% | 2.5% ~ 5.75% | 4.75% ~ 5.75% |

| Indium (In) | 0.01% ~ 0.02% | 0.015% ~ 0.04% | 0.015% ~ 0.02% |

| Silicon (Si) | 0.08% ~ 0.2% | 0.12% max. | 0.06% ~ 0.12% |

| Iron (Fe) | 0.13% max. | 0.09% max. | 0.12% max. |

| Copper (Cu) | 0.006% max. | 0.003% max. | 0.003% max. |

| Cadmium (Cd) | — | 0.002% max. | 0.002% max. |

| Total Impurities | 0.1% max. | 0.1% max. | 0.1% max. |

| Aluminum (Al) | Remainder | Remainder | Remainder |

Low Driving Voltage

This aluminium tank anode provides a stable performance in seawater and electrolytes containing chloride ions as its operating potential is kept between -1.05 to -1.10 volts relative to saturated calomel electrode(SCE).

| Technical Measurement | Performance |

| Open Circuit Voltage (-V) | 1.10 min. |

| Closed Circuit Voltage (-V) | 1.05 min. |

| Current Capacity | 1135 A.h/lbs (2500 A.h/kg) |

| Current Efficiency | 90% min. |

| Consumption Rate | 7.6 lbs/A·y (3.4 kg/A·y) |

Much Lighter in Weight

The aluminium tank anode is less dense than zinc, making it lighter and easier for handling when fitting.

Strict Quality Control

By conforming to ISO 9001:2015 standards, our aluminium tank anode is manufactured, inspected, and tested in accordance with stringent procedures to ensure high quality.

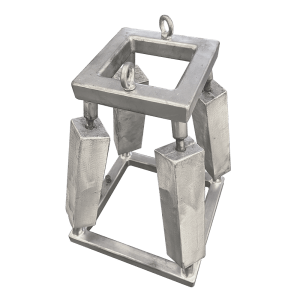

Customized Configurations

Based on over 50 years’ production experience, Jennings Anodes can customize the anode shape, sizes, and service life to meet your specific needs upon request.