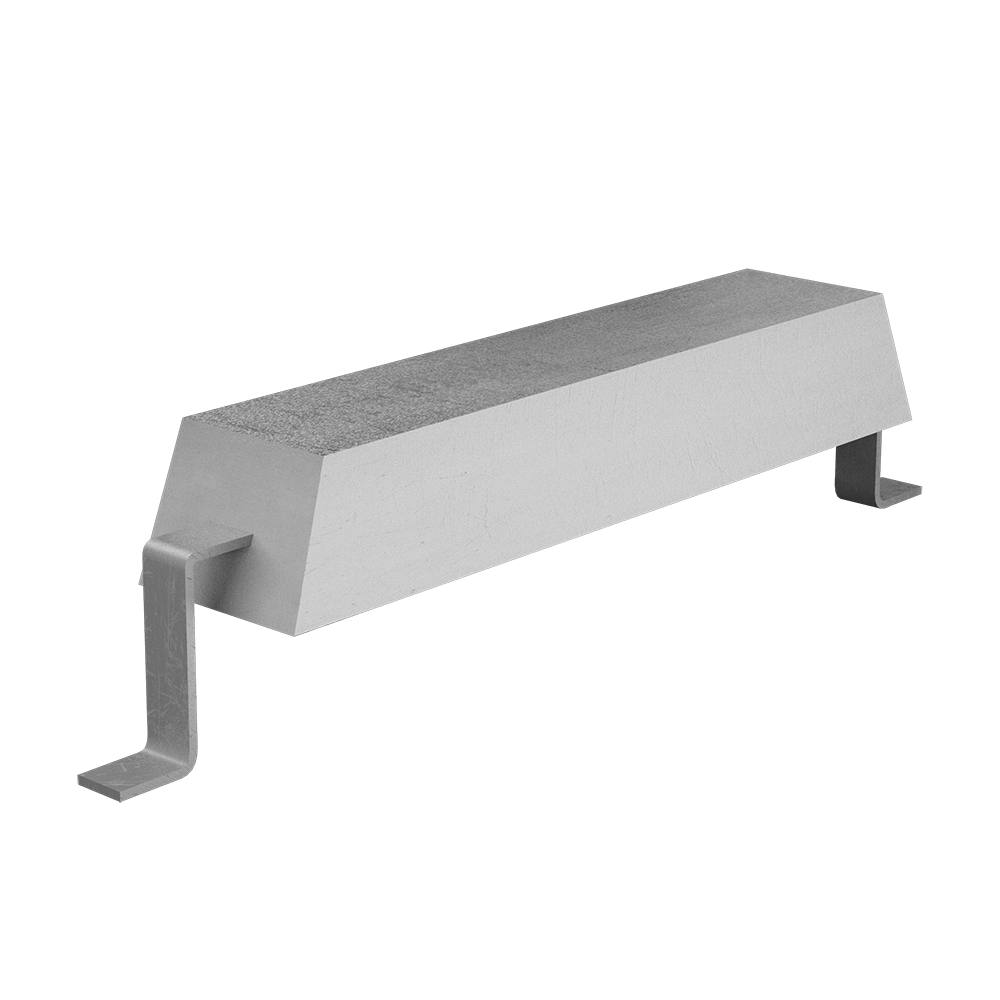

Quality Substrate Material

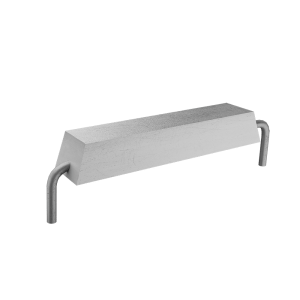

Casted in low-iron, high-purity alloys, our slender stand-off anode is designed as per the standard of ISO, NACE, DNV.

| Element | GALVALUM III | DNV-RP-B401-2011 | GS EP COR 201 |

| Zinc (Zn) | 2.0% ~ 6.0% | 2.5% ~ 5.75% | 4.75% ~ 5.75% |

| Indium (In) | 0.01% ~ 0.02% | 0.015% ~ 0.04% | 0.015% ~ 0.02% |

| Silicon (Si) | 0.08% ~ 0.2% | 0.12% max. | 0.06% ~ 0.12% |

| Iron (Fe) | 0.13% max. | 0.09% max. | 0.12% max. |

| Copper (Cu) | 0.006% max. | 0.003% max. | 0.003% max. |

| Cadmium (Cd) | — | 0.002% max. | 0.002% max. |

| Total Impurities | 0.1% max. | 0.1% max. | 0.1% max. |

| Aluminum (Al) | Remainder | Remainder | Remainder |

Low Driving Voltage

This stand-off aluminium anode provides a stable performance in seawater and electrolytes containing chloride ions as its operating potential is kept between -1.05 to -1.10 volts relative to saturated calomel electrode(SCE).

| Technical Measurement | Performance |

| Open Circuit Voltage (-V) | 1.10 min. |

| Closed Circuit Voltage (-V) | 1.05 min. |

| Current Capacity | 1135 A.h/lbs (2500 A.h/kg) |

| Current Efficiency | 90% min. |

| Consumption Rate | 7.6 lbs/A·y (3.4 kg/A·y) |

Much Lighter in Weight

The stand-off aluminium anode is less dense than zinc, making it lighter and easier for handling when fitting.

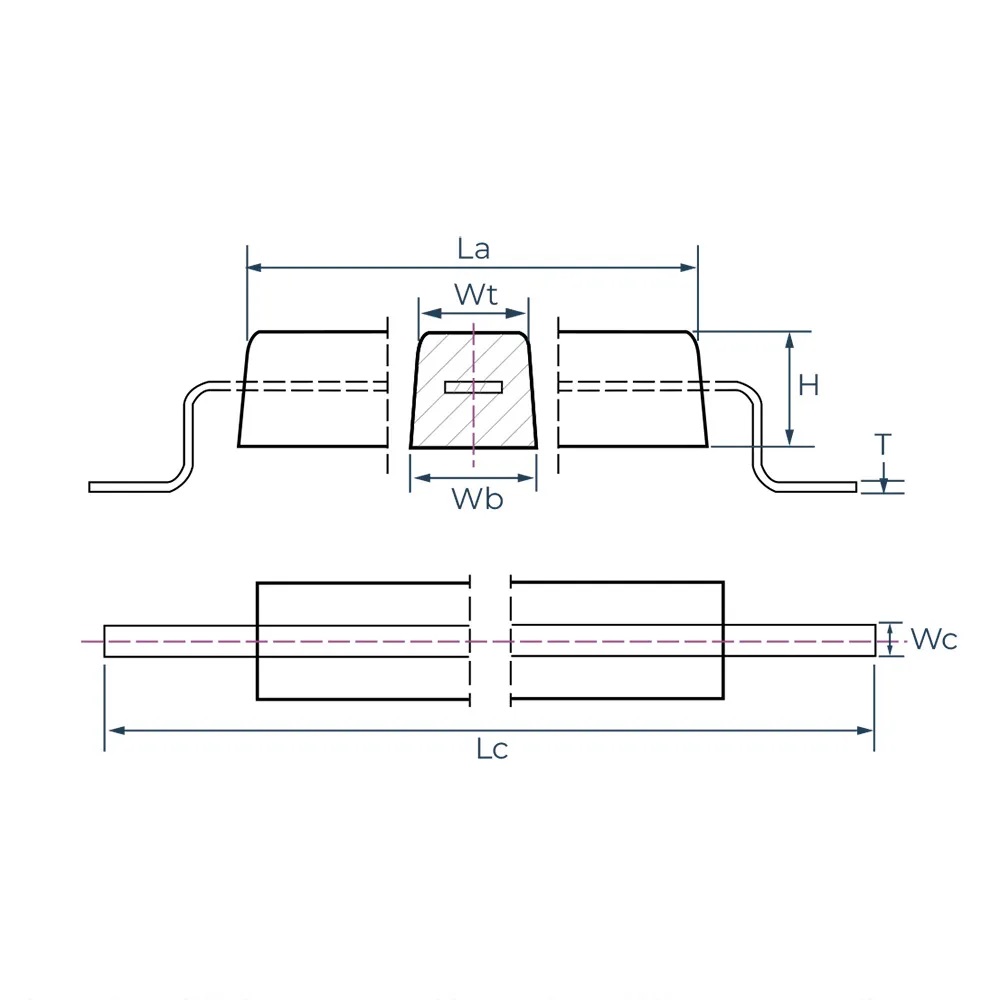

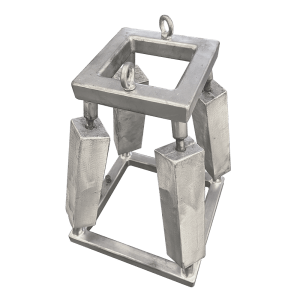

Customized Configurations

Our slender stand-off aluminium anodes are further classified into Short and Long, depending on their ratio of length to width. The length affects the resistivity of the anode and thus its current capacity.

| Item No. | Anode Dimensions | Insert Dimensions | Weight | |||||

| Wt | Wb | H | La | Wc x T | Lc | N.W | G.W | |

| JA-AL-MSF1 | 2.04.5” (115 mm) | 5.3” (135 mm) | 5.1” (130 mm) | 19.7” (500 mm) | 2.0”x0.16” (50×4 mm) | 29.5” (750 mm) | 47.6 lbs (21.6 kg) | 50.0 lbs (22.7 kg) |

| JA-AL-MSF2 | 2.04.5” (115 mm) | 5.3” (135 mm) | 5.1” (130 mm) | 29.5” (750 mm) | 2.0”x0.16” (50×4 mm) | 39.4” (1000 mm) | 71.7 lbs (32.5 kg) | 75.0 lbs (34 kg) |

| JA-AL-MSF3 | 2.04.5” (115 mm) | 5.3” (135 mm) | 5.1” (130 mm) | 39.4” (1000 mm) | 2.0”x0.2” (50×6 mm) | 49.2” (1250 mm) | 94.8 lbs (43.0 kg) | 101.4 lbs (46 kg) |

| JA-AL-MSF4 | 2.04.5” (115 mm) | 5.3” (135 mm) | 5.1” (130 mm) | 49.2” (1250 mm) | 2.0”x0.2” (50×6 mm) | 59.1” (1500 mm) | 118.4 lbs (53.7 kg) | 126.3 lbs (57.3 kg) |

| JA-AL-MSF5 | 6.3” (160 mm) | 8.7” (220 mm) | 7.1” (180 mm) | 27.6” (700 mm) | 2.0”x0.3” (50×8 mm) | 37.4” (950 mm) | 140.7 lbs (63.8 kg) | 146.8 lbs (66.6 kg) |

| JA-AL-MSF6 | 7.9” (200 mm) | 11.0” (280 mm) | 5.9” (150 mm) | 31.5” (800 mm) | 2.0”x0.4” (50×10 mm) | 41.3” (1050 mm) | 168.7 lbs (76.5 kg) | 177.5 lbs (80.5 kg) |

| JA-AL-MSF7 | 7.1” (180 mm) | 8.7” (220 mm) | 7.1” (180 mm) | 33.5” (850 mm) | 2.0”x0.4” (50×10 mm) | 43.3” (1100 mm) | 179.7 lbs (81.5 kg) | 188.9 lbs (85.7 kg) |

| JA-AL-MSF8 | 5.8” (148 mm) | 7.0” (178 mm) | 6.7” (170 mm) | 59.1” (1500 mm) | 2.0”x0.4” (50×10 mm) | 70.9” (1800 mm) | 242.5 lbs (110 kg) | 257.5 lbs (116.8 kg) |

Note: Custom-made configurations are available upon request.