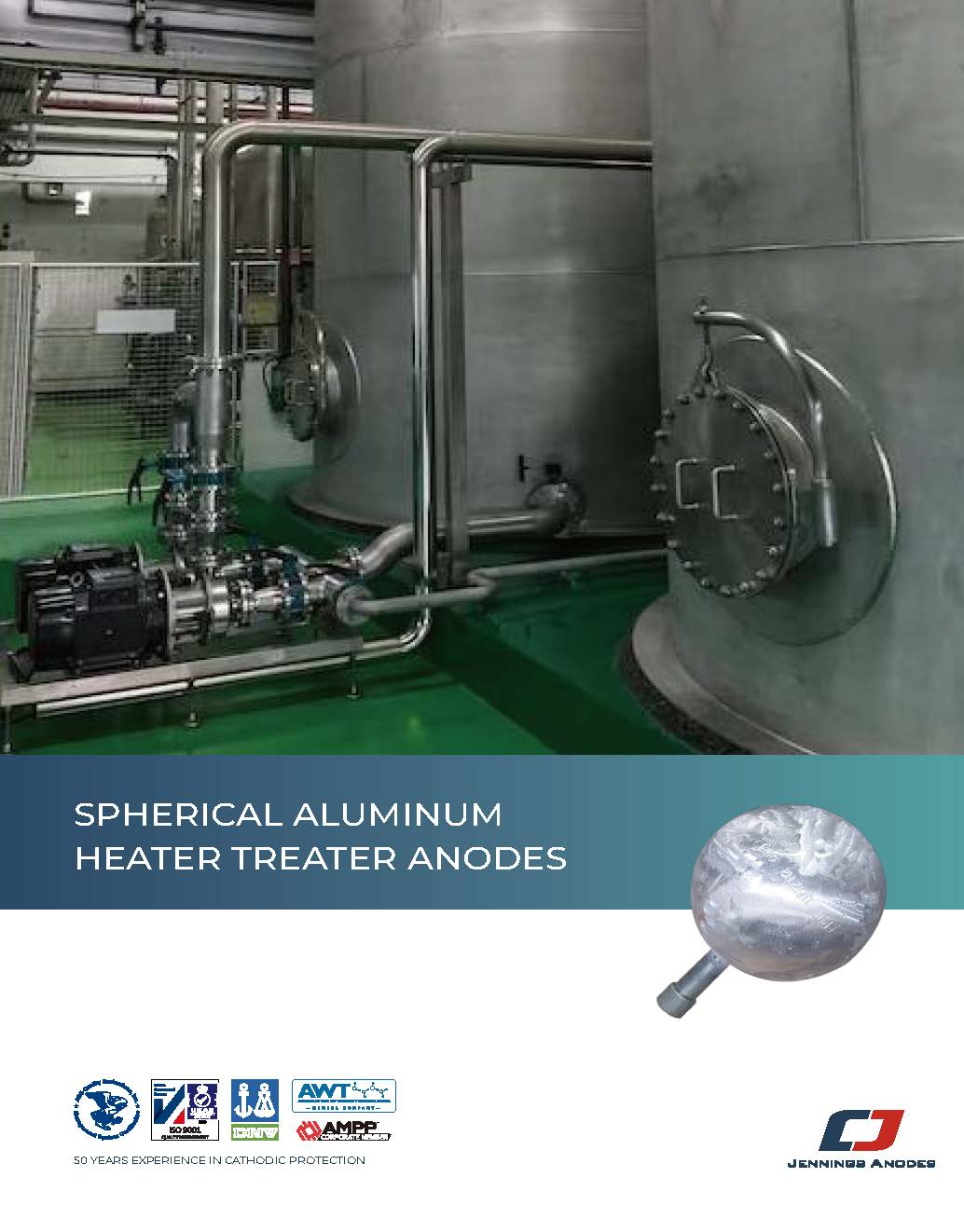

Spherical Aluminum Heat Treater Anode

This aluminum anode ball is a compact easily replaced sacrificial anode which is installed in heat treaters, pressure vessels and other production vessels. The aluminum heater treater anodes work optimally at relatively high temperatures and low chloride saltwater or freshwater environments.

Additional information

| Application | |

|---|---|

| Environment |

Description

Description

Quality Substrate Material

Casted from high-voltage and high-potential alloy, our aluminum ball anode is designed to meet the standard GALVALUM III.

| Element | GALVALUM III | DNV-RP-B401-2011 | GS EP COR 201 |

| Zinc (Zn) | 2.0% ~ 6.0% | 2.5% ~ 5.75% | 4.75% ~ 5.75% |

| Indium (In) | 0.01% ~ 0.02% | 0.015% ~ 0.04% | 0.015% ~ 0.02% |

| Silicon (Si) | 0.08% ~ 0.2% | 0.12% max. | 0.06% ~ 0.12% |

| Iron (Fe) | 0.13% max. | 0.09% max. | 0.12% max. |

| Copper (Cu) | 0.006% max. | 0.003% max. | 0.003% max. |

| Cadmium (Cd) | — | 0.002% max. | 0.002% max. |

| Total Impurities | 0.1% max. | 0.1% max. | 0.1% max. |

| Aluminum (Al) | Remainder | Remainder | Remainder |

Low Driving Voltage

This aluminium ball anode provides a stable performance in seawater and electrolytes containing chloride ions as its operating potential is kept between -1.10 to -1.15 volts relative to saturated calomel electrode(SCE).

| Technical Measurement | Performance |

| Open Circuit Voltage (-V) | 1.10 min. |

| Closed Circuit Voltage (-V) | 1.05 min. |

| Current Capacity | 1135 A.h/lbs (2500 A.h/kg) |

| Current Efficiency | 90% min. |

| Consumption Rate | 7.6 lbs/A·y (3.4 kg/A·y) |

Parameters

The standard anode size is illustrated below. Custom-made shapes, weights and configurations are available upon request.

| Item No. | Ball Diameter | Insert Dimensions | Weight | |||

| ØC | L | NPT | N.W | G.W | ||

| JA–AL–B47 | Ø9.84” (Ø250 mm) | Ø1.3” (Ø34 mm) | 4.0” (102 mm) | 1” | 47.5 lbs (21.5 kg) | 49.5 lbs (22.5 kg) |

Testing

We employ rigorous internal testing standards to ensure the optimum lifespan and performance of our Anodes. Each anode is labelled with a unique serial number for quality tracking. Third party testing is conducted by customer’s special request at extra charge.

| Testing Details | Chemical Composition | Electrochemical Performance | Physical Properties |

| Testing Standard | DNV-RP-B401 | NACE TM0190 | Foundry ITP |

| Testing Content | Chemical Analysis | Circuit Potential / Current Capacity / Current Efficiency / Electrical Resistance | Dimension & Weight / Surface Finish / Steel Insert |

| Equipments | Optical Emission Spectrometer OBLF QSN 750 | Electrochemical Analyzer EPI 200 | Calibrated Digital Measuring Devices |

Packaging Information

Remarks: Custom packing is available upon request.

We have strict packing protocols to guarantee safe delivery of our products. Clear shipping marks and documentation make delivery acceptance straightforward and simple.

Shipping Documents:

- Proforma invoice

- Packing list

- Testing reports (Chemical Composition, Electrochemical Properties Test, Certificate of Compliance)

- Certificate of origin (upon request)