Galvanic anodes, or sacrificial anodes, are used in galvanic cathodic protection systems to extend the life of the steel structure they are protecting. This guide explains what they are, how they work and the different types available.

WHAT ARE SACRIFICIAL ANODES ?

Galvanic anodes (also commonly known as sacrificial anodes) are highly active metals that are used within cathodic protection systems. They effectively prevent or dramatically slow down the oxidation reaction or degradation of the parent steel material most commonly seen as rust.

Galvanic anodes are created from a metal alloy with a more negative electrochemical potential than the metal it will be used to protect. This is why they are often known as sacrificial anodes, as the anode metal is “sacrificed” and so the anodes corrode or are consumed instead of the parent metal.

HOW DO SACRIFICIAL ANODES WORK ?

Galvanic or sacrificial anodes work because they have a stronger or more negative electrochemical potential than the potential of the metal that they are protecting. These sacrificial anodes are then said to behave anodically while the parent metal structure is said to behave as a cathode as the anode is slowly consumed through time while the metal structure remains protected.

With the flow of electrons in one direction, the current will flow between the cathode and anode in the opposite direction.

TYPES OF SACRIFICIAL ANODES

There are a variety of different types of galvanic anodes available, suitable for a range of applications. We manufacture four main types of sacrificial anode in three main alloys that have been specifically developed for use in different environments: magnesium anodes, aluminium anodes, water box anodes and zinc anodes.

MAGNESIUM ANODES

Magnesium anodes are highly electronegative, making them a good option for supplying electrons to more electro-positive steel structures such as pipelines, towers, pilings and bridges. Historically, they have been the most popular anode choice for on-land protection of oil, gas and water pipelines.

There are two main grades of magnesium that have different purities and slightly varying electrochemical outputs. The purer grade of magnesium is more problematic to cast and manufacture and ideally requires noble-gas shrouding and other practices to ensure the anode is free from any inclusion, slag, pitting or any other casting defect.

More than one million of our magnesium anodes have been installed onto structures across the USA and Canada, and we continue to offer the highest quality anodes available.

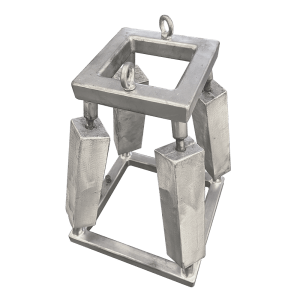

Aluminium Anodes

Aluminium anodes have a slightly lower voltage rate than their magnesium counterparts, but their slower consumption rate makes them ideally suited for seawater and freshwater applications, such as seawater-based vessels, mechanical equipment, marine engineering and harbour facilities, seawater pipelines, ship hulls, ballast tanks, drilling platforms, and wind turbine foundations.

Aluminium anodes also benefit from being very lightweight, with a higher capacity than zinc and a relatively low cost per pound. This means they typically have a longer lifespan so are a popular choice for most off-shore applications.

As aluminium is not considered a pollutant, they are less harmful to the aqueous environment than other options which makes them well suited for use in seawater, as well as brackish and fresh water.

water box anodes

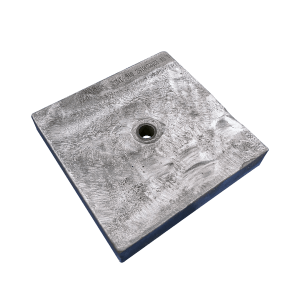

Available in both magnesium and aluminium types (depending on application), water box anodes are an important component in the protection of almost any enclosed water tank or pressurised vessel.

Such tanks, including all domestic hot water tanks, a prone to accelerated corrosion within the steel tank and require relatively small anodes to slow down the internal corrosion.

These anodes are often extruded cylinders of either aluminium or magnesium, and are commonly inserted into the tank via a threaded end-cap.

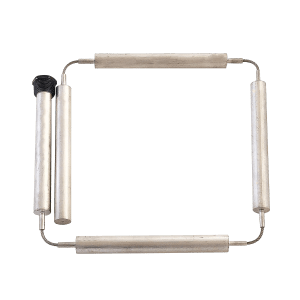

Zinc ribbon anodes

Zinc ribbon anodes offer a flexible, simple, cost-effective and low-maintenance solution to corrosion control.

As little to no maintenance is required, zinc ribbon anodes are a good choice for unattended or hard to reach applications, and are often used in underground situations where the anode can be positioned very close or next to the structure it is protecting. More recently, zinc ribbon anodes are also used in the control of AC mitigation.

Comprising an extended ribbon containing a steel wire core, the zinc ribbon anode offers more than 95% current efficiency, making them a highly reliable option. Our zinc ribbon anodes are tested to temperatures as low as 45 degrees below freezing, as well as temperatures that ensure they can operate effectively in the hottest Saudi Arabian deserts.